The book Chip War clearly illustrates the entire history of the semiconductor industry, from Gordon Moore’s introduction of Moore’s Law and Robert Noyce’s founding of Intel to Morris Chang’s establishment of TSMC. The semiconductor industry has always been a battleground for top players, where even a single misstep can lead to the loss of market position or even ruthless elimination. For example, both South Korea’s Samsung and CPU giant Intel have faced strategic missteps and manufacturing bottlenecks, causing their technology and market share to lag far behind TSMC.

Elon Musk, CEO of Tesla, has utilized a well-known concept called the “Idiot Index” to measure how much more the cost of a finished product is compared to the cost of its basic components. If this index is too high, it indicates that the component design is too complex or inefficient and requires more advanced manufacturing techniques to reduce costs. In the chip industry, companies employ various strategies to cut costs, such as self-development or reducing non-essential auxiliary designs. However, self-development carries risks. Companies may lack experience or fail to design products that meet market demands, which can ultimately lead to failure and the loss of market opportunities.

If I have seen further, it is by standing on the shoulders of giants.

Newton once said, “If I have seen further, it is by standing on the shoulders of giants.” The reason why the chip industry can rapidly develop following Moore’s Law is that those “shoulders of giants” can always be replicated. Chip design companies often purchase mature IP (such as CPU IP and image processing IP) to quickly launch the products that meet the market demands, and integrate these IPs into their technology and products to accelerate the new product design process.

In today’s chip design industry, the most pressing issue is how to prevent end users from receiving defective chips while ensuring high quality, all while considering design costs. This balance often becomes a critical factor in determining whether a chip design company can survive in the competitive market.

iSTART-TEK specializes in Memory Built-In Self-Test (MBIST) and memory Built-In Self-Repair (MBISR) technologies for many years, providing high-quality self-diagnostic circuits for customers. Through these solutions, iSTART-TEK has helped customers repair over 50% of defective chips, significantly improving product yield rates. iSTART-TEK is also the only enterprise in Greater China that have achieved ISO 26262 TCL1 certification, the highest level of software tool confidence certification.

Yield increased by 50%, but area increased by less than 1.5%

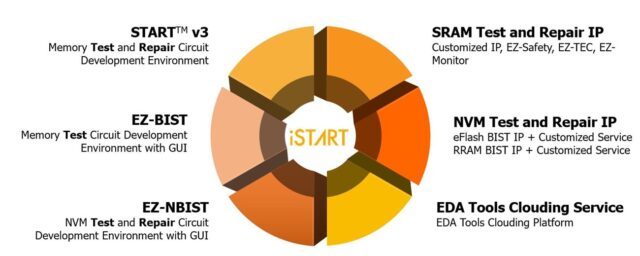

iSTART-TEK’s EDA tools include START and EZ-BIST, while its IP offerings include eFlash BIST, EZ-TEC, EZ-Safety, and EZ-Monitor. The company’s patented customized functions, such as highly efficient memory repair technology—recognized by a Chinese patent—and User-Defined Algorithm (UDA), which have been granted a U.S. patent, enable customers to swiftly complete the necessary testing designs for modern chips. These patented functions ensure high-quality chips with minimal impact on circuit size, with the added circuitry occupying less than 1.5% of the total memory area. As a result, iSTART-TEK’s memory testing and repair solutions provide chip designers with an optimal balance between chip quality and cost efficiency.

iSTART-TEK is committed to delivering highly cost-effective products, helping customers significantly reduce development time and costs. With its competitive pricing and high-quality offerings, iSTART-TEK has become the preferred choice for numerous chip design companies.

iSTART-TEK’s main product line