The advancements in Artificial Intelligence (AI) technology have endowed AI systems with the ability to perceive, learn, reason, analyze, communicate, understand, and solve problems. As semiconductor technology continues to evolve, chip design and functionality have progressed from simple arithmetic logic operations to now incorporating AI capabilities. However, developing AI chips involves rigorous verification processes to ensure stable operation. For instance, Blackwell, a well-known company’s AI chip, faced shipment delays due to design defects. This not only impacted the company’s expected $200 billion revenue in 2025 but also caused significant losses in the product development timelines and reputations of its customers. Therefore, ensuring that large-scale chips meet functional requirements and maintain high yield rates has become a top priority for chip designers during product development.

MBIST and MBISR

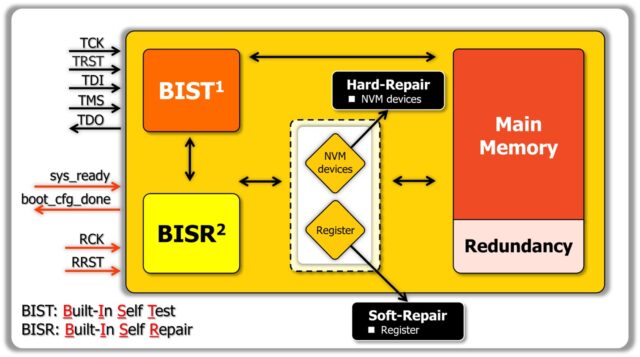

High-quality chips require not only powerful functionality but also comprehensive testing and validation solutions to ensure high yield. Especially in the AI chip field, to meet complex computing demands, various types of memory are embedded in the chips, with memory sometimes occupying more than 60% of the total chip area. Thus, memory yield is one of the critical factors in determining whether an AI chip can function properly. To ensure that memory functions correctly, testing solutions like MBIST (Memory Built-in Self-Test) are widely used. When memory errors are detected, MBISR (Memory Built-in Self Repair) is employed to correct them, improving overall yield.

Features of its repair technology

As one of the few EDA tool and IP providers in the industry offering MBIST/MBISR testing solutions, iSTART-TEK has gained the favor of internationally renowned companies through its patented architecture and highly efficient memory repair technology. The key features of its repair technology are as follows:

- Simplified operation interface: iSTART-TEK’s memory repair technology has surpassed the limitations of traditional template-based design by adopting an innovative Turn-on & Generation approach. This allows customers to easily complete circuit repair and significantly shorten the development cycle.

- High-performance technology: iSTART-TEK offers both Soft Repair and Hard Repair solutions, providing customers with flexible options based on chip performance efficiency or cost requirements.

- Redundancy repair technology: When redundant memory cannot be generated, iSTART-TEK’s “Stand-alone” repair technology can be utilized to achieve self-repair functionality for the memory.

- EZ-Safety is an independent IP that can notify and initiate memory testing in real-time during chip operation. If any defects are detected during testing, EZ-Safety can also perform repairs, ensuring the chip continues to function stably.

These memory repair technologies offer chip designers flexible options and can be applied across various IC designs, particularly in mainstream AI chip development. As the importance of AI applications escalates worldwide, leveraging professional and mature EDA tools becomes essential to achieving satisfactory yields in AI chip production.

iSTART-TEK provides Soft Repair and Hard Repair technologies.